Fenwal DAF - Detect-a-Fire® Detectors

Be Cool - "Detect a Fire!"

Introduction:

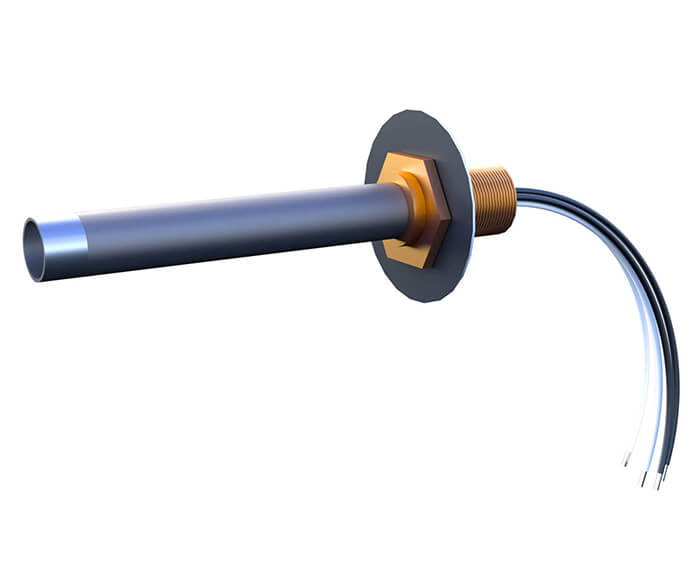

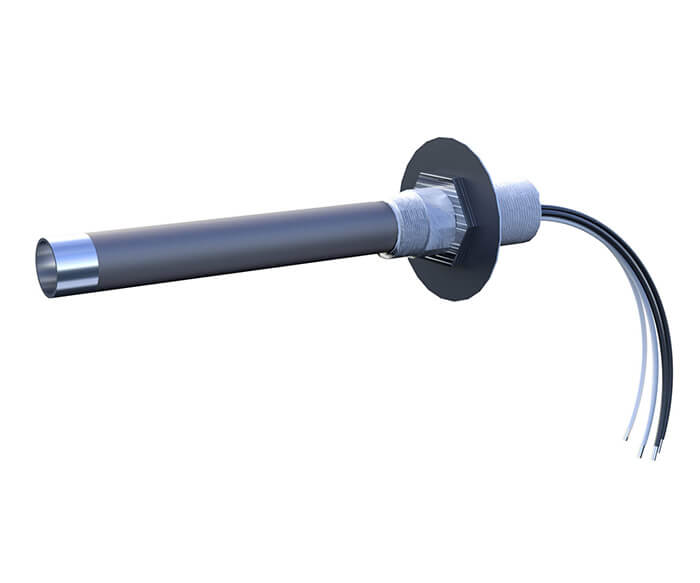

DETECT-A-FIRE® units are the heart of many Fire Protection Systems. These highly reliable devices have been a standard of the industry for over 65 years. Many hundreds of thousands of these units are now in use controlling the release of fire suppression agents such as FM200, CO2, water, foam, wet or dry chemicals. In some systems the device is used as an ALARM device. to sense overheat or fire, and alert personnel. In other systems, it is used as a RELEASE device, to sense fire and actuate fire attack systems.

DETECT-A-FIRE® units have met with wide acceptance because they are designed with RATE COMPENSATION. This provides a unique advantage over both fixed temperature and rate-of-rise types of detectors because only the DETECT-A-FIRE® unit accurately senses the surrounding air temperature regardless of the fire growth rate. At precisely the predetermined danger point, the system is activated.

Available vertical DAF® models:

N/O – Closes at Rise: 27121-000, 27121-020, 28021-005 Series

N/C – Opens at Rise: 27120-000, 27120-022, 28020-003 Series

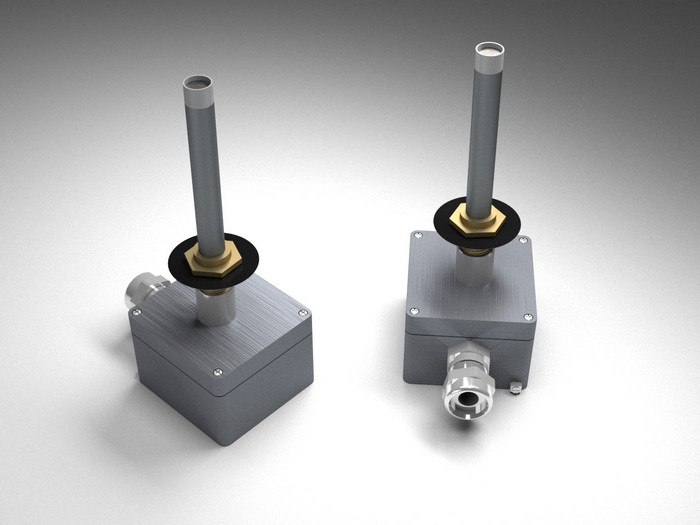

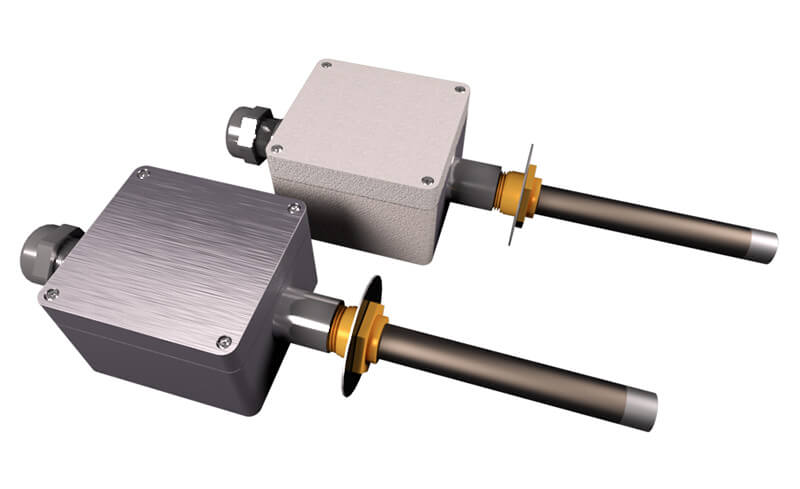

The DETECT-A-FIRE® also can be delivered as a part of a complete systen, built in an Ex-certified junction / mounting box. ATEX and/or EN 54-5 certificates available. Find more information on our Prevent-a-Fire page.

- Factory-set temperatures in various temperature variations from 60°C / 140°F until 385°C / 725°F

- Increadible durability,vibration and schock resistant

- Single Pole Single Throw (SPST) contacts provide fast and easy system intergation

- Contacts available: N/O - Closes or N/C - Opens at Temperature Rise

- Automatic self resetting after cool down

- Extrem reliability of bimetalic construction(free of electronics)!

Typical Applications:

Factories, Businesses, Transformerstations, Shopping Centers, Chemical Industry, Gas-compressors, Heat Exchangers, Buildings, Tanks, Windgenerators, Dryers, Ducts, Machines, Train Heating, Heating Rooms, Paper Machines, Train Air Condition, Hydraulic Compressors, Battery charger stations, Mobile Power Generators, Luxury Yacht Engine Rooms, many more ..

Attention!

According to manufacturer’s notice: “Replace D-A-F detectors after any fire or heat related event, any mechanical damage, or after 10 years of continuous service.” Please find more information in the actual datasheet.

Datasheets & Manuals:

- Detect-a-Fire® DAF Models Datasheet 06 2020 EN

- Vertical Detect-a-Fire® DAF Installation Instructions

- Horizontal Detect-a-Fire® DAF Installation Instructions

- Part Number Identification of DAF Models 2012 EN

- LICO HDL EN 54-5 certified Heat Detectors 05 2022 - English

- LICO HDL EN 54-5 certified Heat Detectors 05 2022 - Deutsch

- LICO HDL ATEX certified Heat Detectors 05 2022 - English

Certificates:

- Vertical & Horizontal Detect-a-Fire® DAF Models CE, DoC

- Vertical & Horizontal Detect-a-Fire® DAF Models FM Certificate

- Vertical & Horizontal Detect-a-Fire® DAF Models FM Report

- Vertical & Horizontal Detect-a-Fire® DAF Models UL 89599 Certificate 600F-7

- Vertical & Horizontal Detect-a-Fire® DAF Models UL E19310 Certificate-474F

Horizontal Detect a Fire units:

Horizontal Heat detectors are designed for locations where appearance is a factor.

The attractive, functional design lends physical protection of the unit while making it suitable for residential, commercial, industrial, mercantile and public buildings, institutions and ships in non-hazardous locations (those classified as “ordinary” under the National Electric Code). Flush mounted units are designed to fit standard 4 inch octagonal electrical boxes and surface mounting units are designed to mount directly on ceilings or on 4 inch electrical junction boxes. Canadian Electrical Code requires mounting only to an electrical junction box.

Available horizontal DAF models:

N/O – Closes at Rise: 27021-000, 27021-001 / OR / N/C – Opens at Rise: 27020-000, 27020-001

Important Note: Horizontal DAF units can not be certified according to EN 54-5 or ATEX.

About Rate Compensation:

Fixed temperature detectors must be completely heated to alarm temperature and therefore a disastrous lag in time may occur with a fast rate fire. Rate-of-rise devices, on the other hand, are triggered by the rate of increase in ambient temperature and are subject to false alarms caused by harmless, transient thermal gradients such as the rush of warm air from process ovens.

The secret of the unit’s sensitivity is in the design. The outer shell is made of a rapidly expanding alloy which closely follows changes in surrounding air temperature. The inner struts are made of a lower expanding alloy. Designed to resist thermal energy absorption and sealed inside the shell, the struts follow temperature changes more slowly.

A slow rate fire will heat the shell and struts together. At the “set point”, the unit will trigger, actuating the alarm or releasing the extinguishant.

A transient rush of warm air up to 40ºF /min. may expand the shell, but not enough to trigger the unit. By ignoring transient warm air excursions, the DETECT-A-FIRE unit virtually eliminates false alarms prevalent with rate-of-rise devices.

If a fast rate fire starts, the shell will expand rapidly. The struts will close, actuating the alarm or releasing the agent. The faster the fire rate of growth, the sooner the DETECT-A-FIRE unit will react.

Copyright & ownership: all Fenwal related Trademarks, Copyrights, Data and Patents are owned by Fenwal

Das Melden von Feuer ist eine Grundfunktion:

Übermäßige Hitze jedoch, es muß dabei gar kein Rauch vorhanden sein, ist eine potentielle Gefahr für das Entstehen von Feuer oder Explosion. Mitunter ist damit eine Früherkennung von zu hoher Temperatur erforderlich. Die Möglichkeit, vor Ausbruchs eines Feuers, wirksame Gegenmaßnahmen einzuleiten, kann Leben retten und hohe Sachwerte schützen.

Durch den Einsatz von 1 oder 2 oder mehreren gleichen oder verschiedenen Schalttemperaturen kann eine effektive (Vor-) Erfassung eines fehlerhaften Temperaturanstieges erfolgen. Das System kann damit auch redundant gleiche Schalttemperaturen überwachen und melden.

Wärme/Hitze kontrollieren, Überhitzung und Feuer/Brand melden.

Auszug von Einsatzgebieten: Heizanlagen & Heizräume, Trocknungssysteme, Absauganlagen, Windkraftwerke, Gasturbinen, Industrieanlagen, Motorräume, Kompressoren, chemische Fabriken, Marine, Gas- & Ölindustrie, Bahntechnik, Energieverteiler, Tankanlagen, Schmelzen, Saunas & Wellnessanlagen und vieles mehr.

Information für alle PAF-Systeme:

Hitzedetektor für besondere Bereiche, kann zur Vermeidung von Feuer von Feuer oder von Explosion beitragen.

Das System besteht aus 1 oder mehreren HDL Hitze-Detektoren LICO, einem LICO Alarmpanel und einem ATEX-zertifizierten Netzteil, Schock- Staub-, Feuchte- und Temperaturfest, Schaltkontakte hermetisch abgedichtet (IP67) Verschiedene Schalttemperaturen von 60 – 385°C(siehe Katalog DAF Detect-a-Fire, Fenwal). Es ist mit dem LICO Alarmpanel möglich sowohl Überhitzung als auch Feuer zu erfassen und zu melden.

Optionen: DAF-Schalter in Voll-Edelstahlausführung, Ex-zertifizierter Netzteil – Niederspannung, Industrie-Server-EDV

Information für alle CFD-Systeme:

CFD – Continuierlicher Feuer Detektor, Hitzedetektor für besondere Bereiche, es kann zur Vermeidung von Feuer oder von Explosion beitragen.

Es ist im wesentlichen ein Feuervermeidungssystem, ist jedoch gleichermaßen als Feuermeldesystem angewandt. Das CFD System ist speziell bei sehr hohen Temperaturen eingesetzt.

Das Herz des Systems besteht aus einem langen Sensorelement, welches an jedem beliebigen Punkt des “Kabel” bei Erreichen der Nominaltemperatur binnen Sekunden leitend wird und damit Alarm auslöst.

Copyright & ownership: all Fenwal related Trademarks, Copyrights, Data and Patents are owned by Fenwal