Prevent-a-Fire & HDL Marine

Stay Cool at Sea – Prevent a Fire!

Introduction:

LICO’s certified HDL (Heat Detector LICO) heat detectors are engineered specifically for the demanding conditions of maritime and offshore environments. Built around the proven, rate-compensated Kidde / Fenwal DAF (Detect-a-Fire) technology and

Ex d-certified DAF sensors, HDL detectors deliver reliable and precise thermal protection where safety is critical and failure is not an option.

Each HDL unit is predominantly custom-built and tailored to the specific requirements of hazardous and industrial marine applications. All products are rigorously tested and certified for operation at the highest permissible ambient temperatures, ensuring dependable performance across a wide range of real-world conditions. Our mission is simple: to provide the right heat detection solution for the right application — without compromise.

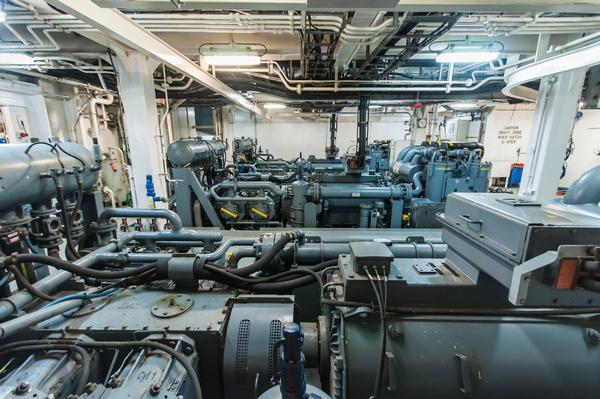

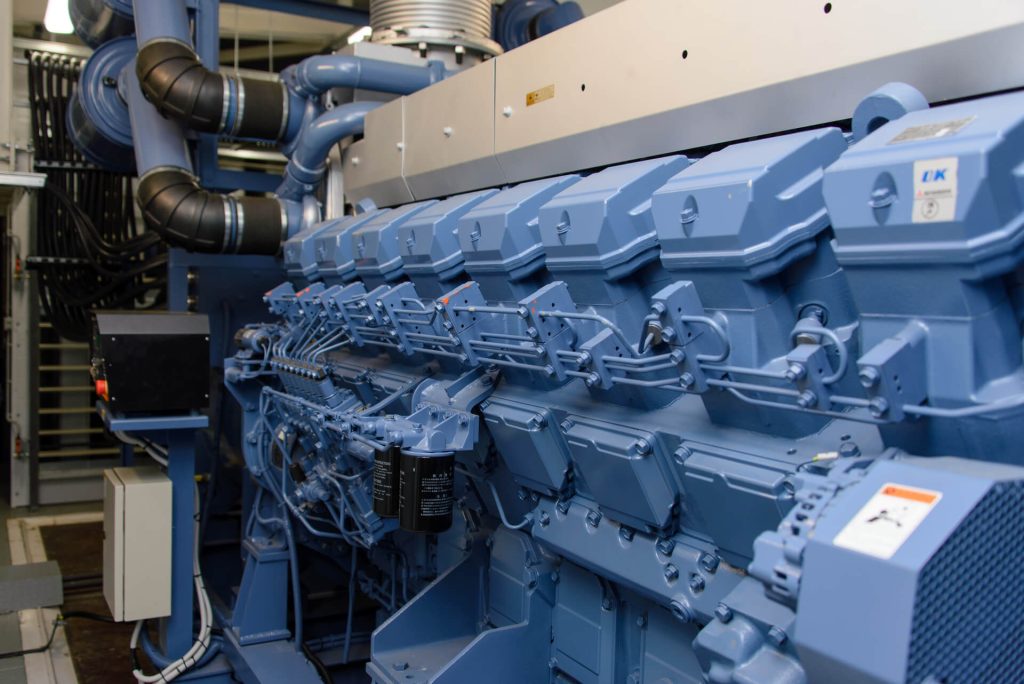

LICO marine heat detectors protect a broad spectrum of maritime and safety-critical installations, including engine rooms, machinery spaces, yachts, container vessels, harbours, shipyards, offshore platforms, wind generators, power and transformer stations, gas turbines, and other environments where elevated temperatures may lead to overheating or fire. Wherever heat is generated at sea or offshore, LICO delivers proven protection — designed to perform when it matters most.

Marine-Certified Heat, Overheat & Fire Detection You Can Trust

- Custom made Our HDL heat and overheat detectors are based on bimetallic, heat detector switches, free of electronics, to provide the best reliability in high temperature applications, also during harsh environmental conditions.

- Simplicity goes through in our product family to provide easy installation and a very cost effective maintenance.

- Various alarm temperature settings are available from 60°C until even 385°C in potential free contacts, which makes fast and easy system integration in practically every already existing- or new systems.

- Our DNV MED and DNV Type Approval certificates ensure the highest level of technical solutions.

Actual HDL Datasheets & Manuals:

- LICO HDL MED Marine certified Heat Detectors 01 2026 - English

- LICO HDL MED Marine certified Heat Detectors 01 2026 -Deutsch

- Installation, Operation & Safety instructions

Configure your own heat detector fast and easy by using our part number configurator. Please click HERE!

What is the advantage of Rate Compensated heat detectors?

Improved Sensitivity to Rapid Temperature Changes: These detectors are designed to react to a rate of temperature increase, which allows them to detect rapid temperature changes indicative of a potential fire, rather than only reaching a fixed temperature threshold.

Reduced False Alarms: Since they are not triggered by slow temperature increases (like those caused by gradual heating or minor changes), rate-compensated heat detectors are less likely to give false alarms from non-threatening conditions, such as normal environmental temperature fluctuations.

Faster Response: The detector responds more quickly to fire hazards, as it considers both temperature and the speed at which the temperature is rising. This is especially useful in environments where heat can build up rapidly.

Higher Accuracy in Critical Environments: These detectors are ideal for environments with fluctuating or harsh temperature conditions, such as industrial or manufacturing areas, ensuring a reliable and effective fire detection system.

Wide Range of Applications: Rate-compensated heat detectors can be used in various environments, from engine rooms to industrial factories, and are particularly useful where traditional temperature-based heat detectors might fail to respond appropriately.

Marine Applications:

Engine rooms and auxiliary machinery spaces, generator rooms, exhaust and funnel systems, fuel handling and fuel treatment areas, battery rooms and energy storage systems, electrical switchboards and control cabinets, propulsion systems, bow and stern thrusters, hydraulic power units, HVAC and ventilation ducts, galley exhaust systems, cargo holds and Ro-Ro decks, pump rooms, ballast water systems, technical voids and service shafts, containerized power units, offshore platforms and modules, ferry and passenger vessel machinery spaces, workboats and service vessels, luxury yacht engine rooms and technical compartments, naval and special-purpose vessels, and many more areas where reliable heat and overheat monitoring is essential to prevent fire and ensure operational safety.

Attention!

According to manufacturer’s notice: “Replace D-A-F or HDL detectors after any fire or heat related event, any mechanical damage, or after 10 years of continuous service.” Please find more information in the actual relevant datasheet.

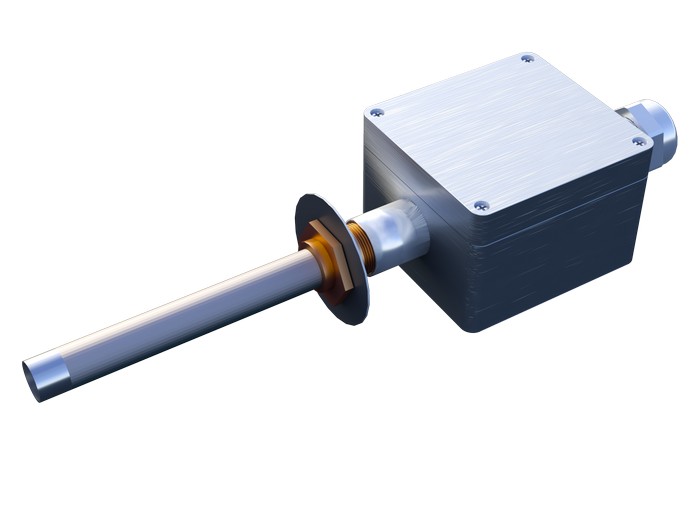

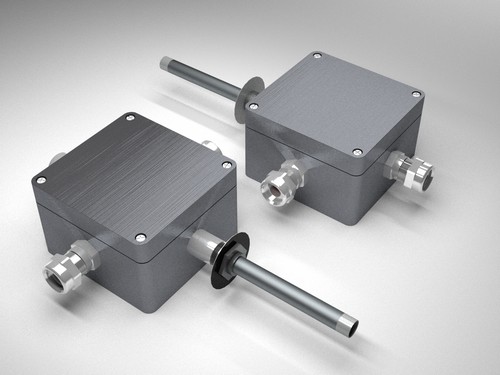

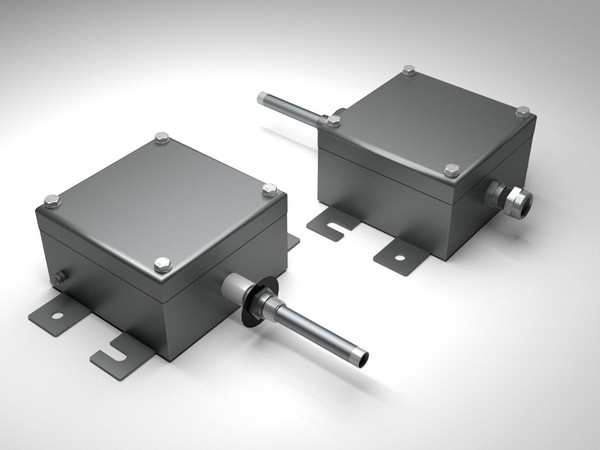

HDL-2 & HDL-3 Series:

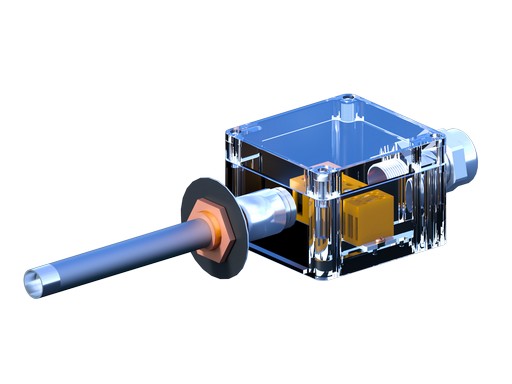

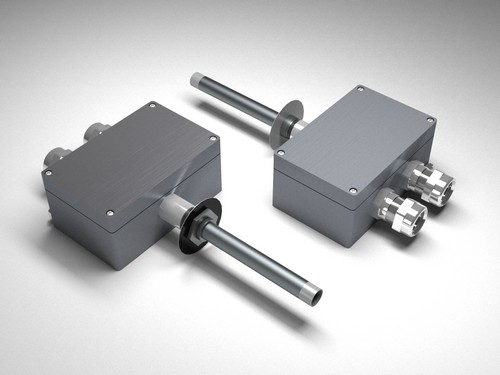

Our best seller, compact, industrial Heat Detector LICO series. Made mostly for low and middle range temperature

(until 130 °C – recommended max. 150 °C) applications. The assemblies include the Kidde/Fenwal DAF bimetallic heat detector of choice(restrictions may apply), an unpainted(HDL-3) or epoxy polyester painted(HDL-2) aluminium enclosure with IP67 with one or two cable entries with Ex certified, metallic cable entry glands mounted or threaded cable entry of choice and further more,

Ex certified, high temperature wiring terminal blocks for wiring.

Both, HDL-2 and HDL-3 Series have DNV MED & DNV Type Approval Certificates.

Applications:

Sauna applications, transformer stations, exhaust systems, painting rooms, wind generators, factories, heat exchangers, buildings, server rooms, machine rooms and custom built machines, containers, storage tanks, power plants, trains, heating rooms, dryers, ducts, paper machines, air conditions systems, filter systems, hydraulic compressors, chemical plants, train heating, engine testing rooms, battery charger, luxury yacht engine rooms and many more, where you need to monitor and control heat / overheat to prevent fire or explosion.

HDL-2 & HDL-3 features:

- HDL-2 painted epoxy polyester / HDL-3 unpainted (raw)

- Kidde / Fenwal DAF detector of choice

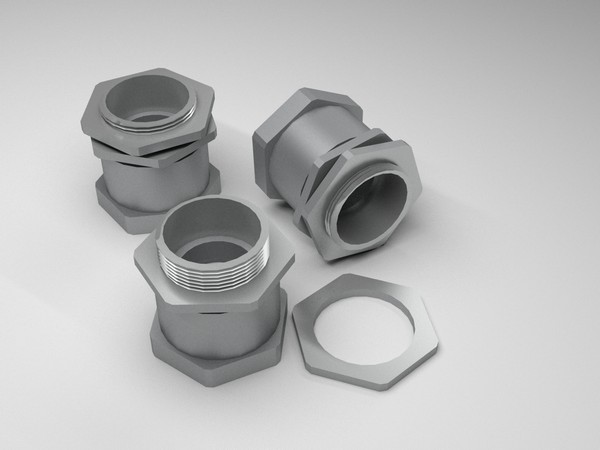

- One or two cable entries with gland(s) or threaded entries only

- 2x2 or 2x4 pole High temperature wiring terminal blocks

- Internal and / or external earth points

.

- Compact, small size (junction box approx. 80 x 75 x 57 mm)

- Price economic

- Solid, easy to install

- Designed until max. 150 °C / 300 °F

- IP 66 Tested & Approved

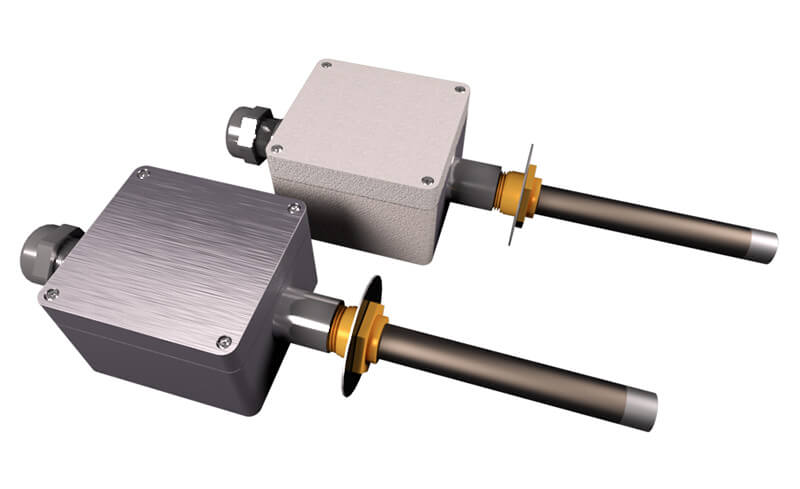

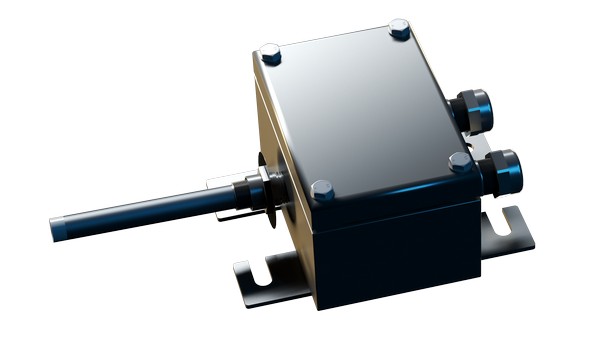

HDL-3XL & HDL-5 Series:

Our HDL-3XL Series are based on the HDL-3/-2 basic models, however system integrators and installers often need more space for the wiring and mounting the necessary Serie Line or EOL – End Of Line resistors / devices. Please let us know what you need, we do our best to fulfill your needs. Made mostly for low and middle range temperature (until 130 °C – recommended max. 150 °C) applications.

HDL-5 Series are made with a larger aluminium box, to have even more space inside and be suitable for higher temperatures, even up to 725 °F / 385 °C using special, Ex certified, ultra high temperature wiring terminal blocks.

Both, HDL-3XL and HDL-5 Series have DNV MED & DNV Type Approval Certificates.

Applications:

Sauna applications, transformer stations, exhaust systems, painting rooms, wind generators, factories, heat exchangers, buildings, server rooms, machine rooms and custom built machines, containers, storage tanks, power plants, trains, heating rooms, dryers, ducts, paper machines, air conditions systems, filter systems, hydraulic compressors, chemical plants, train heating, engine testing rooms, battery charger, luxury yacht engine rooms and many more, where you need to monitor and control heat / overheat to prevent fire or explosion.

HDL-3XL features:

- Junction box size approx. 80 x 125 x 57 mm

- Kidde / Fenwal DAF detector of choice

- One, two or three cable entries with gland(s) or threaded entries

- Extended: 2x4 or 2x6 or 2x8 pole high temperature wiring terminal blocks available

- Series & EOL resisistors are available

- Internal and / or external earth points

- IP 66 Tested & Approved

HDL-5 features:

- Junction box size approx. 120 x 122 x 80 mm

- Kidde / Fenwal DAF detector of choice

- One, two or three cable entries with gland(s) or threaded entries

- Ultra high temperature, cermaik wiring terminal blocks: from 2x2 until 2x6 pole

- Series & EOL resisistors are available

- Internal and / or external earth points

- IP 66 Tested & Approved

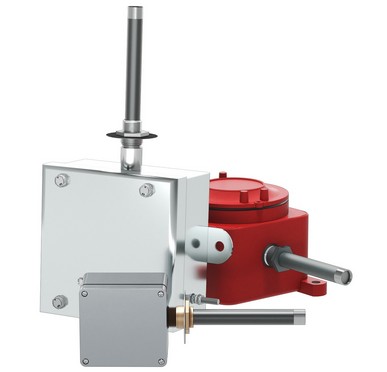

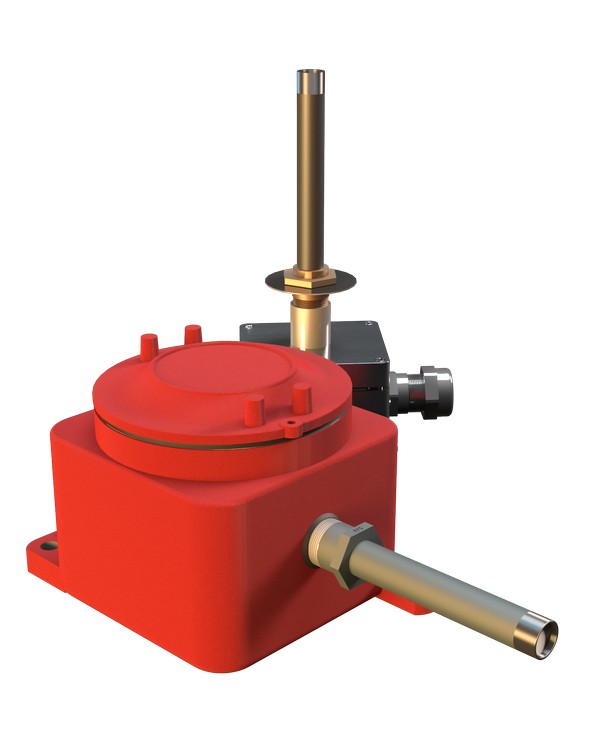

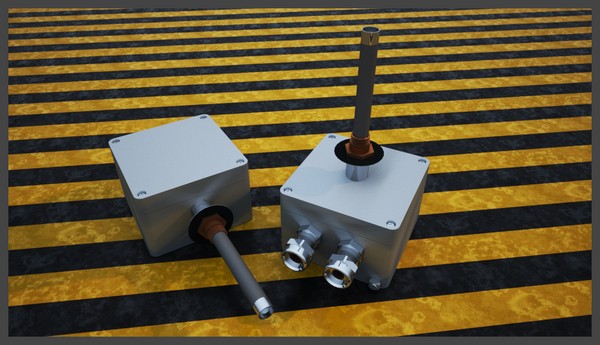

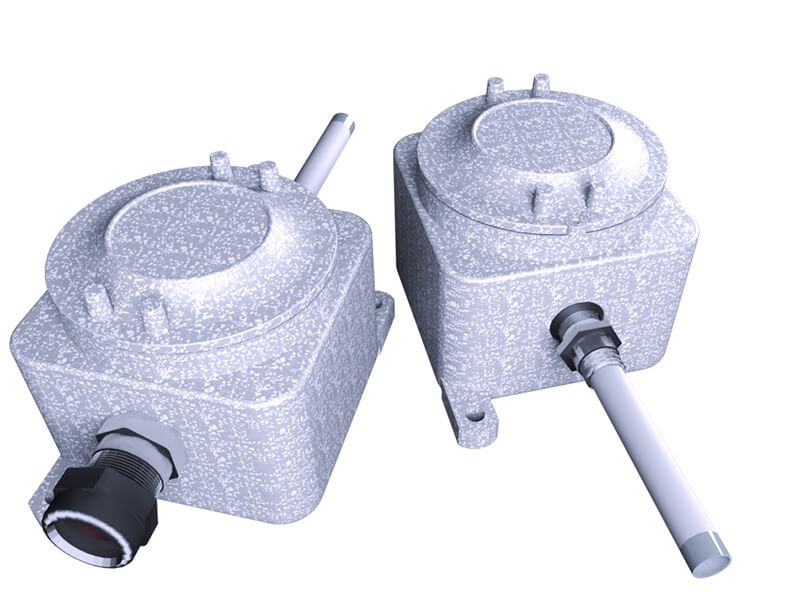

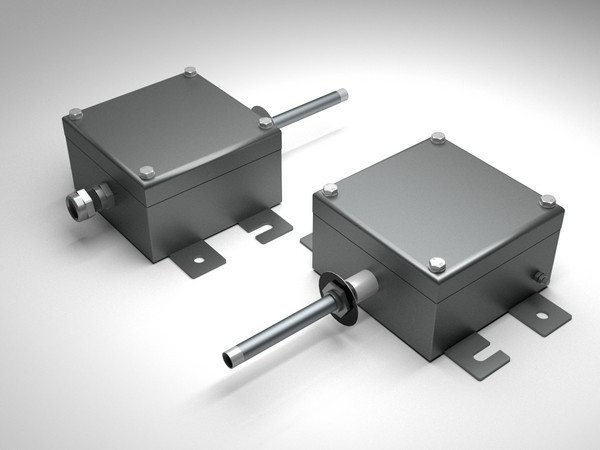

HDL-6 & HDL-6XL Series:

There are harsh & heavy industrial applications where standard solutions are not enough. Our massive, robust HDL-6 and HDL-6XL series are withstand any kind of harsh, industrial & marine requirements fulfilling the latest standards. They are designed for low and also high temperatures, from 60 °C until 385 °C. Serie Line or EOL – End Of Line resistors are available also for very high temperatures.

Both, HDL-6 and HDL-6XL Series have DNV MED & DNV Type Approval Certificates.

Applications:

See above, just concentrated mostly on: gas-turbine and turbine applications, on-shore / off-shore platforms, oil & gas industry, marine, Ex d – flameproof applications and many more, where you need to monitor and control heat / overheat to prevent fire or explosion.

HDL-6 features:

- HDL-6 junction box size approx. 120 x 120 x 116 mm

- Chromate primed and polyester powder coated for added protection against corrosion until 180 °C

- Kidde / Fenwal DAF detector of choice

- Special Kidde / Fenwal detectors for Ex d use!

- One, two or three cable entries with gland(s) or threaded entries

- Extended: 2x4 or 2x6 or 2x8 pole high temperature wiring terminal blocks available

- Series & EOL resisistors are available

- Internal and external earth points

- IP 66 Tested & Approved

HDL-6XL features:

- HDL-6XL junction box size approx. 150 x 150 x 130 mm

- Chromate primed and polyester powder coated for added protection against corrosion until 180 °C

- Kidde / Fenwal DAF detector of choice

- Special Kidde / Fenwal detectors for Ex d use!

- One, two or three cable entries with gland(s) or threaded entries

- Ultra high temperature, cermaik wiring terminal blocks: from 2x2 until 2x6 pole

- Series & EOL resisistors are available

- Internal and external earth points

- IP 66 Tested & Approved

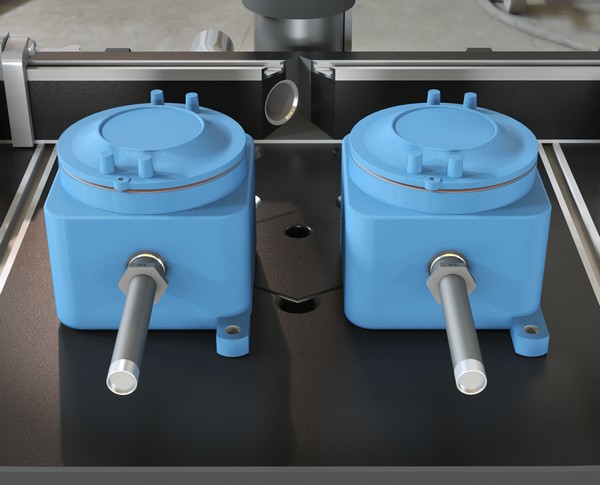

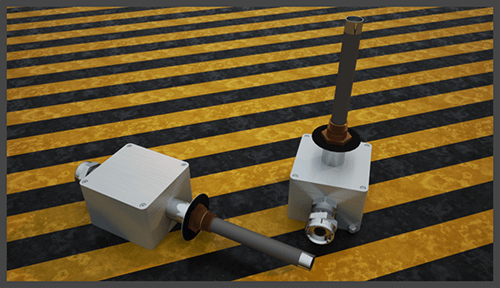

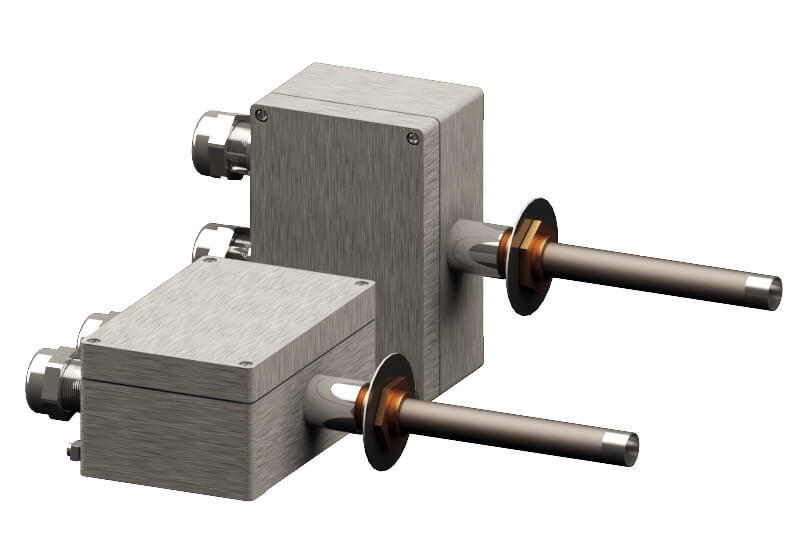

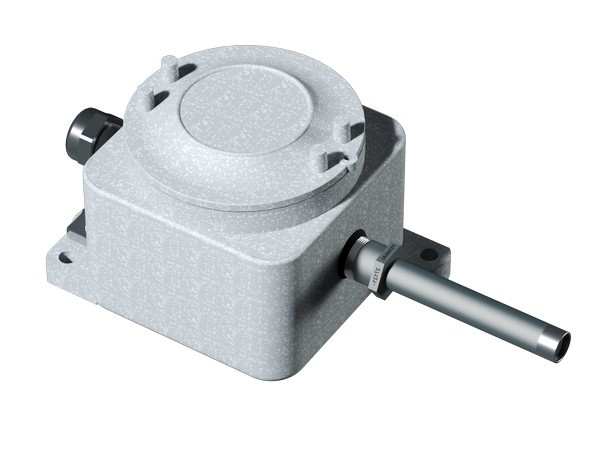

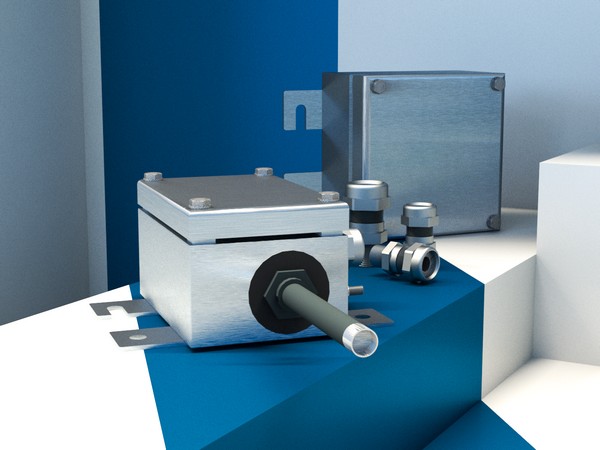

HDL-7 & HDL-7XL Series:

Have an industrial kitchen or chemical plant? Need a suitable, long lifetime heat detector for your food production which can withstand against chemicals and acids? need to control temperature in highly radiated areas in a nuclear power plant?

Our fully stainless steel HDL-7 & HDL-7XL series are at your service!

They are suitable for low and also high temperatures, from 60 °C until 385 °C. Serie Line or EOL – End Of Line resistors are available also for very high temperatures.

Both, HDL-7 and HDL-7XL Series are available in EN 54-5 (LICO standard) and / or ATEX certified variations.

Marking of both certificates is possible on request.

Applications:

See above, just concentrated mostly on: food processing, industrial kitchen applications, chemical factories, high radiated areas (like in nuclear power plants)

and many more, where you need to monitor and control heat / overheat to prevent fire or explosion.

HDL-7 features:

- HDL-7 junction box size approx. 126 x 126 x 87 mm

- Mirror-polished or electropolished stainless steel 1.4404 (316L), 1.5 mm

- Kidde / Fenwal DAF detector of choice

- One, two or three cable entries with gland(s) or entries

- Extended: 2x4 or 2x6 or 2x8 pole high temperature wiring terminal blocks available

- Series & EOL resisistors are available

- Internal and external earth points

- IP 66

HDL-7XL features:

- HDL-7XL junction box size approx. 156 x 156 x 97 mm

- Mirror-polished or electropolished stainless steel 1.4404 (316L), 1.5 mm

- Kidde / Fenwal DAF detector of choice

- One, two or three cable entries with gland(s) or entries

- Ultra high temperature, cermaik wiring terminal blocks: from 2x2 until 2x6 pole

- Series & EOL resisistors are available

- Internal and external earth points

- IP 66

Optional / Recommended Accessories:

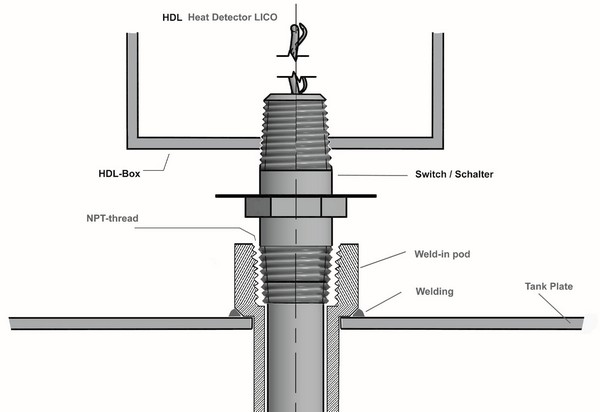

Screw in Pod / Weld in Pod

A popular solution in gas, oil and chemical industry. Also widely used in hydraulics, frying and drying applications as well as in oven and heating controls.

Easy installation! Drilling the hole and welding in the weld-in pod allows easy installation and safe service without contact to the tank media.

Stainless-steel NPT Screw-in-adapter with outside & inside NPT-thread instead of outside welding.

Custom made modifications are available according to actual cost.

Attention!

Depending on the application, the Screw-in & Weld-in pods / protective sleeves can change or even block the rate of rise function of the detector! Afterwards, the detectors work like a safety thermoswitch with fixed alarm temperature only! For new installations we highly recommend to test a sample unit before taking any further action. LICO accepts no responsibility for any non-conformity, damage or loss of value.

New!

Laser-engraved enclosures / optional upgrade:

LICO’s laser-engraved product labels and enclosure markings provide a durable and maintenance-free solution for identifying critical product information. Unlike printed or adhesive labels, laser engraving ensures permanent readability, even in harsh environments exposed to high temperatures, chemicals, UV radiation, or mechanical wear. This makes it an ideal choice for safety-critical, industrial, and hazardous-area applications where traceability and compliance are essential. The result is a clean, precise, and long-lasting identification method that remains legible throughout the entire product lifecycle.

Intrinsically safe barriers:

Intrinsically safe (IS) barriers are essential components in hazardous areas, ensuring that electrical signals and power remain within safe limits to prevent ignition. Designed for Ex ia applications, these barriers provide the highest level of protection, making them suitable for Zone 0 environments where explosive atmospheres are continuously present. They work by limiting voltage, current, and power, preventing sparks or excessive heat that could trigger an explosion. IS barriers are commonly used in industries like oil & gas, chemical processing, and mining, where safety is critical. Their robust design ensures reliable signal transmission while maintaining compliance with international safety standards (such as ATEX, IECEx).

Screw through adapters:

Screw through adapters are quite useful when the detectors shall be mounted through a plate or a kind of isolation and the detectors need to be in the high temperature or critical zone and all the junction box, cables etc. must be out.

Custom made modifications are available according to actual cost.

Detector extension adapters:

The detector extension adapters have similar functions like the screw through adapters above. They are to extend or shorten the length between the detector and the junction box.

Custom made modifications are available according to actual cost.

Portable bimetallic heat detector tester:

We help you to control heat & overheat wherever is needed!

Fire warning is a basic function:

Often early Detection of excessive high temperatures is most critical. Occasionally an early Detection of too high temperatures is most vital. Excessive heat, even without the presence of smoke, can be a potential hazard of fire or explosion. The prevention of a potential fire, caused by excessive heat, allows corrective action to avoid igniting flames. In conclusion – effective action can save lifes and protect high value buildings and assets. The system can be either used for single or redundant Heat Detection using 2 equal switching temperatures. It also can be using by programming 2 (or more) different switching temperatures. The flexible and highly effective system gives accurate data acquisition and warning of excessive high temperatures. Control Heat, alarm Overheat (OVHT), alarm fire Application References: Heating plants, Heating Rooms, Dryers, Exhaust systems, Wind power generators, Gasturbines, Industrial plants,Gas & Oil-industry, Enginerooms, Compressors, Chemical Plants, Energy-plants, Sauna & Wellness-facilities & many more.

Information for all PAF-Systems: The Heat Detectcion for special applications. It can add safety in Fire-/Explosion prevention. The System contains a LICO Alarmpanel, 1 or more HDL Heat Detectors LICO and optionally an ATEX-certified Power Supply.All units are Dust-, Humidity- and Temperature-safe,switching contacts hermetically sealed (IP67),Various rate compensated switching temperatures from60 – 385°Care available. (see catalogue DAF Detect-a-Fire, Fenwal)It ispossible with the LICO Alarm-panel to collect Overheat- & Fire-Information and to alarm the both individually. Options:Switch fully stainless steel, Ex-certified Low VoltagePower Supply, Industrial Server UPS.