PLATON Metal Tube Flowmeters

May the flow be with you...

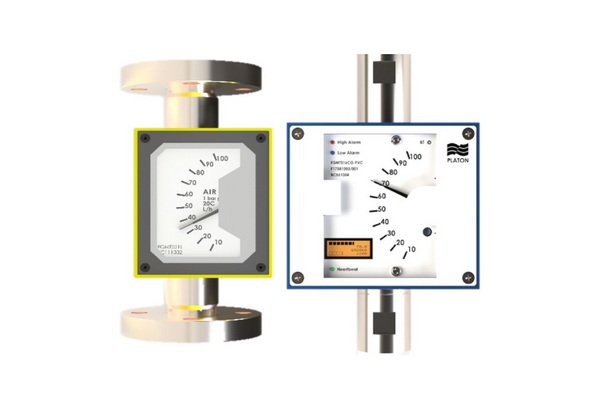

PLATON Metal Tube GMTE Flanged or Screwed VA Flow meter – NEW!

GMT & GMTE metal tube flowmeters are variable area meters of totally welded stainless steel construction. Liquid or

Gas flowing up the tapered flow tube lifts the float to an equilibrium position, dependent on flow rate, and a magnetically

coupled pointer indicates this flow on an external scale. The large meter indication is easily visible at a distance, with

the pointer moving over a 160° scale. Each scale is produced specifically for the fluid involved and process conditions

expected: several flow ranges are available for meters of each standard line size. All gas flow meters are supplied with

an integral piston damper to smooth out flow pulsations.

Installation is simple, in a vertical section of flow line: meters can be supplied with EN, ANSI or other standard flanges,

or BSP or NPT screwed connections.

The flow tube’s robust construction with no glands or seals to leak, means the meters are suitable for high pressure

applications, or extremes of temperature. While the GMT is totally self-contained and needs no external power, the

GMTE combines a mechanical meter with an electronic 3-wire transmitter. The GMTE features, adjustable low and high

alarm with LED indicator, totalisation, 4-20 mA output, adjustable averaging of the flowrate reading, heartbeat indicator,

and backlit LCD display.

- ½” - 4” line sizes

- Mechanical flowmeter

- Electronic flowmeter

- Clearly visible meter

- Scaled for process fluids

- Easy installation—flanged or screwed

- Robust, simple construction

- Pulsation damper on gas meter

Datasheet:

Operation & Maintenance Manual:

PLATON Metal Tube GMT Flanged VA Flow meter

GMT metal tube flowmeters are variable area meters of totally welded stainless steel construction. Liquid or Gas flowing up

the tapered flowtube lifts the float to an equilibrium position, dependent on flow rate, and a magnetically coupled pointer

indicates this flow on an external scale. The large meter indication is easily visible at a distance, with the pointer moving

over a 1500 scale. Each scale is produced specifically for the fluid involved and process conditions expected: several flow

ranges are available for meters of each standard line size. All gas flow meters are supplied with an integral piston damper to

smooth out flow pulsations.

Installation is simple, in a vertical section of flow line: meters can be supplied with EN, ANSI or other standard flanges, or BSP or NPT screwed connections.

- ½” - 4” line sizes

- No power required

- Clearly visible meter

- Scaled for process fluids

- Easy installation—flanged or screwed

- No glands or seals

- Robust, simple construction

- Pulsation damper on gas meter

Datasheet:

Operation & Maintenance Manual:

PLATON Metal Tube GMT Screwed VA Flow meter

Part of the Platon GMT Variable Area flowmeter family, models GMTB and GMTS are brass or Stainless Steel tube flowmeters with female screwed connections. With 1/2”,1”and 2” BSP/NPT threaded fittings standard, the meters are ideal for arduous industrial service as an alternative to large glass tube flowmeters. They have particular advantages for gas or liquid flow measurement at high pressures and temperatures, where the fluids are opaque or dark colored or to provide higher operational security for dangerous or toxic materials.

- Economic construction

- BSP/NPT Screwed end fitting

- Brass or Stainless Steel

- Wide flow ranges

- Sizes 15, 25, 50mm. 1/2”, 1”, 2” bore

- Integral damping on gas flow lines

- Local indication

- Calibration for wide range of gases and liquids

Datasheet:

Operation & Maintenance Manual:

PLATON SC250 Metal Tube Flowmeter

Flowmeters are based in the variable area principle. The metering system consists on a calibrated orifice and a conical float. The force from the fluid, as it flows from the bottom to the top, displaces the float until it reaches an equilibrium point. Each float position represents an area between the float and the orifice.

This area corresponds to a flow rate.

- Metallic tube with a robust construction

- Indication by means of magnetic coupling

- High performance measurement in extreme working conditions and highresistance to corrosion

- Low pressure drop

- Damping mechanism to avoid float bounces in gas and steam applications

Datasheet:

Operation & Maintenance Manual:

- Not available

Flowing with precision:

Unlock the Power of Precision: Why Analogue Industrial Flowmeters Matter. In the fast-paced world of industrial operations, accuracy is non-negotiable. Discover why analogue flowmeters remain a cornerstone of efficiency and reliability in measuring fluid flow. From their robust design to real-time data insights, analogue flowmeters offer unparalleled precision for critical processes. Explore the enduring necessity of analogue technology in optimizing performance and ensuring seamless operations. Dive into our comprehensive guide and unleash the potential of analogue flow measurement for your industry needs. Elevate your workflow, elevate your results—experience the difference with PLATON flowmeters today.